2K garage floor coating / garage paint / garage floor paint / epoxy resin floor coating for garage, workshop, basement W707 2.5–20 kg

2K epoxy resin system

Extremely heavy-duty

Chemical resistant

- 41,90€

52,90€- 41,90€

- Unit price

incl. VAT

Free shipping within Germany!

Order now and receive your goods within a few days at no extra cost!

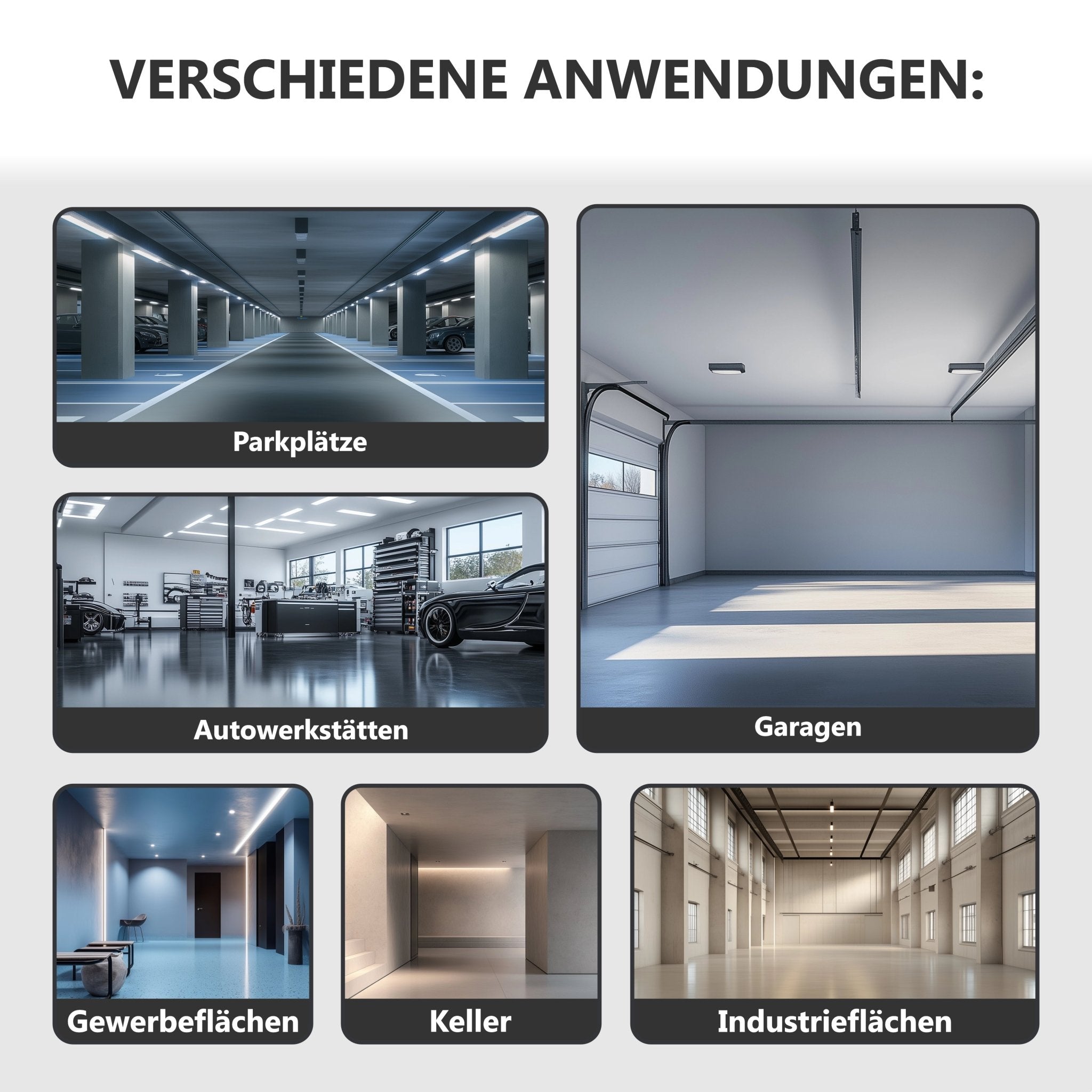

⬤ PREMIUM 2K GARAGE FLOOR COATING: Our high-quality, water-based 2-component system offers maximum resistance and durability. Ideal for garages, workshops, basements, storage areas, and industrial floors.

🔴 VERSATILE & suitable for almost all mineral substrates: Perfect for concrete, cement, screed, hard asphalt screed, and even fiberglass. Reliably protects against abrasion, scratches, and plasticizer migration from car tires.

🟡 HIGHLY RESISTANT & CHEMICALLY RESISTANT: Withstands gasoline, motor oil, brake fluid, road salt, and other aggressive substances. Ideal for heavily used surfaces—resists heavy loads from cars, motorcycles, lifting platforms, and machinery without wear or peeling.

⬤ OPTIMAL ADHESION & EASY APPLICATION: Best used in combination with the W703 WO-WE primer, the coating penetrates deeply into the substrate, prevents delamination, and ensures an extremely strong bond with the floor.

🔴 HIGH COVERAGE & ECONOMICAL: Approx. 250–350 g/m² per coat (average approx. 300 g/m² per layer). With two coats and a total average consumption of approx. 600 g/m², 2.5 kg covers up to 4 m², 5 kg up to 8 m², 10 kg up to 16 m², and 20 kg up to 32 m² of floor area. Consumption may be higher on highly absorbent substrates.

🟡 MADE IN GERMANY 🇩🇪: Quality without compromise—manufactured to the highest German standards with strict quality controls for outstanding durability, maximum resistance, and excellent workability.

⬤ EASY TO MAINTAIN: Satin-gloss, lightly textured surface provides increased safety and easy cleaning. Dust, dirt, and liquids can be removed effortlessly.

🔴 EASY APPLICATION WITH ROLLER: Best applied with a paint roller, ensuring an even, professional coating without streaks or bubbles.

🟡 LOW ODOR: The water-based formulation contains no harmful solvents and ensures a pleasant application—ideal for indoor use.

⬤ CUSTOM DESIGN WITH COLOR CHIPS POSSIBLE: Can be combined with color chips for visual enhancement and additional slip resistance—ideal for a modern and stylish floor coating.

W707 2K Garage Paint

W707 by WO-WE is a high-quality coating specially developed for garage floors and other concrete or cement surfaces in indoor areas.

Our 2K coating is characterized by high abrasion resistance and easy cleaning. It also reliably protects garage floors against oil, chemicals, road salt, and general contamination.

For optimal durability and load resistance, we recommend applying the coating in two coats.

Consumption: approx. 250–350 g/m² per coat (average approx. 300 g/m² per layer). With two coats and an average total consumption of approx. 600 g/m², 2.5 kg covers up to 4 m², 5 kg up to 8 m², 10 kg up to 16 m², and 20 kg up to 32 m² of floor area. Consumption may be higher on highly absorbent substrates.

W810 is a ready-to-use special cleaner for optimal surface preparation. Removes wax, grease, dirt, rubber abrasion, and ensures excellent adhesion.

W703 is a solvent-free primer for floor coatings that improves adhesion and scratch resistance. Ideal for concrete, screed, tiles, indoor & outdoor use.

The WO-WE floor coating tool set includes everything needed for applying epoxy resin and leveling compounds. High-quality materials for professionals and DIY users.

WO-WE 2K garage floor paint – the ideal solution for long-lasting protection and a highly resistant surface.

Color chips for creative and individual surface design.

WO-WE W758 glass beads improve the slip resistance of floor coatings. Fine grain, durable, visually discreet, easy to apply, and easy to maintain.